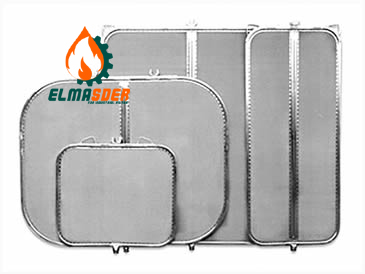

وحدة تصفية الأسطوانة الفراغية الدوارة

وحدة DRAM تمتص الماء من الوسط لفصل الماء عنها

من خلال الامتصاص (Vakom) وفصل المنتج على السطح ، وتشكيل الكعكة.

التخصصات الرئيسية:

– مصانع الزيت

– مصانع الاعلاف

The technique is well suited to slurries, and liquids with a high solid content, which could clog other forms of filter. The drum is pre-coated with a filter aid, typically of diatomaceous earth (DE) or Perlite. After pre-coat has been applied, the liquid to be filtered is sent to the tub below the drum. The drum rotates through the liquid and the vacuum sucks liquid and solids onto the drum pre-coat surface, the liquid portion is “sucked” by the vacuum through the filter media to the internal portion of the drum, and the filtrate pumped away. The solids adhere to the outside of the drum, which then passes a knife, cutting off the solids and a small portion of the filter media to reveal a fresh media surface that will enter the liquid as the drum rotates. The knife advances automatically as the surface is removed.

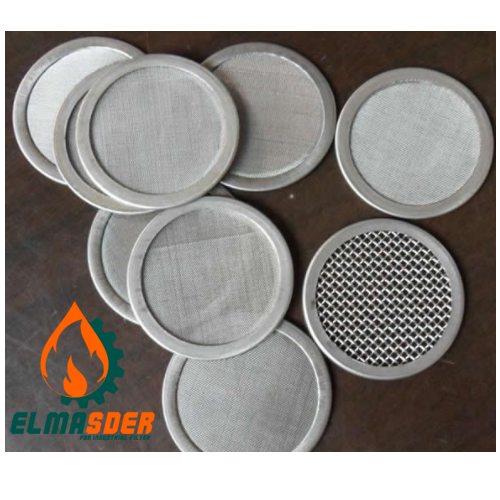

Our range of Rotary Vacuum Drum Filter Cloths

-

Our wide range of woven and non-woven media allows you to balance throughput, cake discharge, and long-life.

-

High particle retention, bursting and tearing strength, and abrasion resistance of the fabric besides chemical and thermal compatibility are of importance. Besides abrasion resistance is required as the process of removal of the dried cake involves scraping

-

Our quality Filter Cloth withstands the rigorous scraping process used to remove the dried cake.

-

Quite often, we recommend a double layered fabric to ensure longevity of the filter cloth and better separation. Hence, we also offer a knitted nylon backing fabric that can used underneath the top cloth to provide a cushion and stability for the cloth as it moves through the Rotary Drum process

-

Innovative agitator rake design ensures solids remain in suspension and avoids

sediment in the system tank for better materials distribution -

Wide range of choices for drum material to suit process demand– polypropylene, carbon steel (unlined or rubber-lined), stainless steel, as well as other materials